CeramicSpeed

Behind The Brand

Denmark, the land of Lego, Hans Christian Andersen and spectacular fjords. Look a little closer though and you will also find one of the bicycle industry’s most recognisable and respected component manufacturers, CeramicSpeed. We headed out to Holstebro to learn more about the people behind the brand.

Waking up to grey skies and a chill in the air, Jimmy Rusbjerg, CeramicSpeed’s European aftermarket sales manager arrived in a CeramicSpeed stickered up van to pick myself and Sigma Sports photographer, Jake, up from the hotel and transport us fifteen minutes down the road to the CeramicSpeed HQ. Located on the outskirts of the town, the nondescript industrial estate did not elude to the treats waiting for us inside the modest CeramicSpeed complex.

A warm welcome greeted us as we stepped through the doors into what can only be described as a corridor of CeramicSpeed history. From pro team bikes to some of the biggest bearings we have ever laid eyes on, it soon became apparent this was no ordinary component manufacturer.

Video is unable to play due to Privacy Settings.

Adjust your Cookie Preferences to Opt-in "YES" to "Functional Cookies".

Working with Pro Teams

Soon we were introduced to Dennis Løh, CeramicSpeed’s sponsor liason guru, the man tasked with building a relationship between the athlete and pro teams. Dennis explained his role within CeramicSpeed and how he moved from Bang Olfusen to the company over six years ago now after he found himself riding with CeramicSpeed founder Jacob Csizmadia.

Working closely with athletes such as Peter Sagan and the Deceuninck - Quick-Step Cycling team, Dennis explained how feedback from the pros plays a crucial part in product development, with riders and teams demanding only the best when it comes to performance and reliability.

Dennis would be our very own personal mechanic for the course of our visit and quickly whipped away our bikes to give them the CeramicSpeed treatment.

The CeramicSpeed Oversized Pulley Wheel System

Both Jake and I would be having the Shimano specific CeramicSpeed Oversized Pulley Wheel System fitted to our bikes. Far from just a rather smart looking derailleur upgrade, the oversized pulley wheel system has been meticulously designed for unparalleled performance and reliability.

With everything from design to production and shipping under one roof, we took the opportunity to follow the pulley wheel system from idea to the finished, ready to ship product.

Where it all began

CeramicSpeed was established in 2004 by Jacob Csizmadia, a world-class, record-breaking speed skater, who famously developed and produced his very own ceramic bearings for his inline skates to break the 24-hour inline speed skating world record, around a Danish supermarket!

This obsession with efficiency didn’t end with inline skates. Jacob soon realised this drivetrain efficiency could be translated across to bicycles. Living just up the road from Jacob was a certain Mr Riis who was managing the CSC Tiscali team. Jacob joined the team at the Tour de France that year to supply the Cervelo bikes with ceramic bearings. The seed had been sewn, the pros were won over.

Starting out in his house, Jacob soon realised the business was growing fast and began hiring. The team grew and now, nearly 20 years on, CeramicSpeed kit out some of the fastest bikes and riders in the world. The bikes and technology may have moved on but the focus on making the world’s best components definitely has not and the company now employs over 80 members of staff, located in three locations, including a base out in Boulder, Colorado.

The Community

An ever-growing team it may be but the tight-knit community aspect remains firmly in place. We were to experience this first hand as once our bikes had been fitted with the OSPW systems we were to join the Wednesday lunch ride. Taking place every week, this was a chance for all members of the CeramicSpeed company to put down tools and go for a 1.5 hour spin, blow away the cobwebs and socialise with their colleagues.

Eight of us headed out for the ride, with CEO, Jacob, leading the ride. It was a typical Danish spring day, with the wind blowing, the skies grey and a chill in the air but that didn’t dampen spirits as we revelled in the quiet lanes and newfound upgraded efficiency of our drivetrains.

Not just a road ride, the company also offers a lunchtime walk as well as a mountain bike ride for employees. A really nice touch and one that brings together all the departments. Arriving back at the CeramicSpeed HQ the community feel continued with all the staff eating lunch together in the canteen.The smiles said it all, this was an inclusive and enjoyable working environment.

Fed and watered, it was time to meet some of the members of the CeramicSpeed family. First up was Carsten Ebbesen who heads up the R&D department, speaking about his experience in engineering and passion for efficiency Carsten explained his passion for cycling, whether that be road in the summer or gravel riding through the forests that litter the area.

R&D is where ideas are formulated and products are born. Working on CeramicSpeed's SRAM Eagle Oversized Pulley Wheel System, Carsten was excited about being able to go from idea to testing to production in such a small space of time, what with all the departments based at the headquarters.

Next on our tour of the complex, we paid the production team a visit. A clinical space, operating with military precision, Dennis guided us through the process and explained the lining up of products is not just for the cameras, it is to ensure every step is ticked off and nothing is missed. Michael, manning one of the work stations, demonstrated how the components went together and we tested by eye and feel to ensure no irregularities were present.

The Man Behind the Marketing

A man who is familiar with the performance benefits CeramicSpeed products have on the professional sporting stage, the next member of the team we were to meet was CeramicSpeed's chief marketing officer Ben Powell.

Originally growing up in Wales, Ben has spent a spell in Lanzarote, where he met his now wife, Helle Frederiksen, a professional triathlete before working out in Boulder to help grow CeramicSpeed’s stateside arm. Having worked in the Danish headquarters for six years, Ben is charged with working on projects such as Eurobike Show stand design all the way through to marketing products for press launches. Ben explains the close-knit community and inclusive nature of the business means literally anyone can pitch an idea and it will be considered, taken on and potentially produced if it’s commercially viable.

Ben then went about showing us the dispatch area. A room that provides stock for their entire distribution network, the ability to move fast and react to last-minute orders or requests from partner brands or distributors ensures there is little wait time for products.

The Testing Process

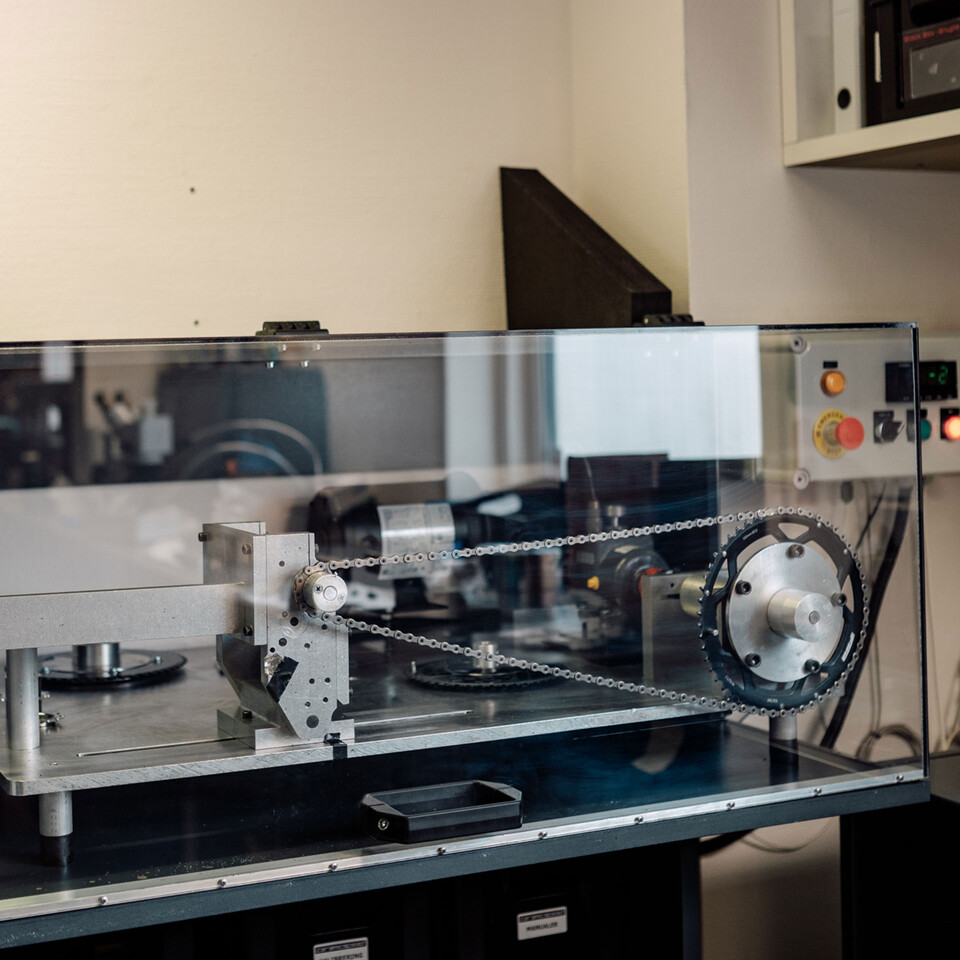

CeramicSpeed is growing fast and this was more than evident as we were welcomed into a portacabin on the grounds of the headquarters. Stepping inside we were greeted by a whirring of machines and some of the most advanced testing equipment in the bicycle industry. Everything from the durability of chains to the strength of wheel bearings was being tested. With bike computers monitoring distance, this thorough process is so well regarded in the industry that even other component manufacturers are sending their products over for testing.

Out of This World

Visiting a second portacabin and you could be confused for thinking you were entering a top-secret NASA laboratory, what with the word ‘UFO’ plastered on the door. Although there were no signs of extraterrestrial life there were some out of this world processes in place. This was the home of the CeramicSpeed UFO Shimano 11-Speed Chain, a dynamic lubricant coated chain that can save 2-5 watts over a 40km race course and is designed with racing in mind.

Looking to the Future

From design to production to shipping and marketing the products, you could say CeramicSpeed are in a comfortable position, but this is not a brand that likes to sit on their laurels. Taking the Eurobike Show in Germany by storm last year, CeramicSpeed’s innovative Driven bike turned heads and pushed the boundaries of what is possible when it comes to drivetrain performance.

We were lucky enough to take a closer look at this one of a kind system, mounted to a Cervelo P5 at the headquarters. A chain and derailleur free design, the concept has been proven to increase optimal efficiency by up to 99% and create 49% less friction than rival’s flagship drivetrains. Swapping a chain for a pinion drive shaft design, Driven utilises CeramicSpeed’s world-leading bearing technology and equips the system with 21 hybrid bearings. 58% lighter and 2.3 times harder than traditional steel, these bearings are more efficient which ultimately equates to more speed out on the road.

With our visit coming to an end, what can we conclude? It is clear to see, from designers to production personnel, the CeramicSpeed employees are passionate about cycling, the products they work with and the ethos Prioritising producing the most efficient components on the market, their founder Jacob is set on making, you, the consumer as fast as you can be.